Industry-ready. Designed for clear industry goals.

We listened. Supplier prices are skyrocketing. Yields are unpredictable. And competition is fierce. We analyzed every component and reduced every profit margin to create our most affordable sorter. Bringing you Bühler quality and 75 years of industry-leading expertise at an unbeatable price.

In line with Bühler’s vision of innovating for a better world, SPARK invites everyone to access food safety standards through optical sorting.

With SPARK, companies can access quality and sustainable productivity to create safe food for all without the high price tag.

- Easy to manage

- Multi-productivity

- Zero rejects

- Bühler quality

Meet SPARK, a revolution in simplicity and reliability

Critical design elements explained:

- Zero rejection concept to avoid product loss.

- Several modules available from 1 to 10 trays.

- Bühler has developed full-color HD cameras.

- New high-definition IR camera.

- Five times faster setup thanks to “Hue Saturation Value”.

- Higher size sorting capability.

- DynamoAI, newly developed sorting mechanism.

- Twice as much light thanks to full-spectrum LED lighting.

- Easy to use, easy to operate for everyone.

Sorting, simplified

Key features

Hue Saturation Value

HSV is the fastest and easiest way to set up and sort with the highest possible productivity without deep dependence on skilled personnel/operators. SPARK is five times faster to set up compared to previous models.

Sorting by size

Experience the new DynamoAI engine for simple undersized and oversized sorting tasks.

Ease of Use

Thanks to the newly developed sorting algorithm, SPARK is easy to operate. From the dashboard to the engine, everything is designed for ease of use, encouraging maximum productivity without the need for highly skilled operators.

Reflective and Transparent Sorting Modes

SPARK can sort in reflective and/or transparent sorting modes. This basic function is linked to the product mode.

Bühler SPARK Pro+

Key Features

Designed for Productivity

New Developments That Change the Situation

Localization Services:

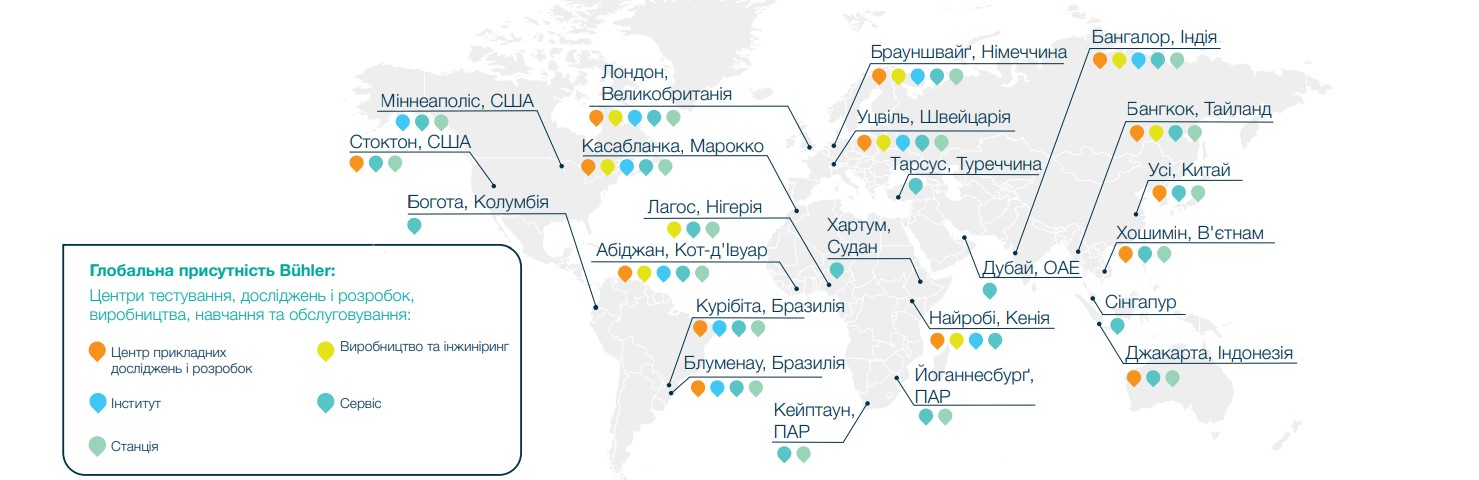

Application, Training and Service Centers

Bühler customers are represented in more than 140 countries worldwide. With customer services such as maintenance, spare parts supply and training courses, you can be sure that your optical sorters are operating efficiently, at optimum capacity and with maximum return on investment.

Today, Bühler has more than 25,000 color sorters installed worldwide, operating in production facilities of all sizes and helping customers achieve higher productivity and profitability.

With our global presence, customers can benefit from our wide range of local capabilities, including equipment supply, service and local customer support. In addition, we have test centers in key grain markets, including India and China, each staffed by some of the world’s leading grain technology experts. With more than 150 years of engineering experience, Bühler can meet the diverse needs of grain handling, processing and storage in each region by developing appropriate technological solutions for grain processing and added value for its customers.

Color Sorting Solutions

Applications

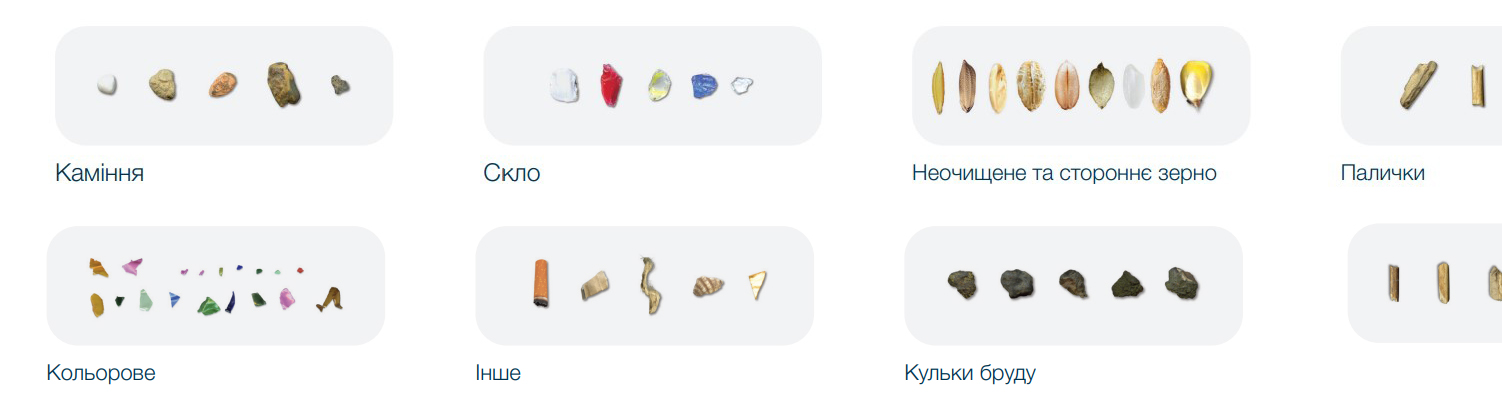

Defects and foreign materials

Bühler Intelligent Color Sorting Solutions

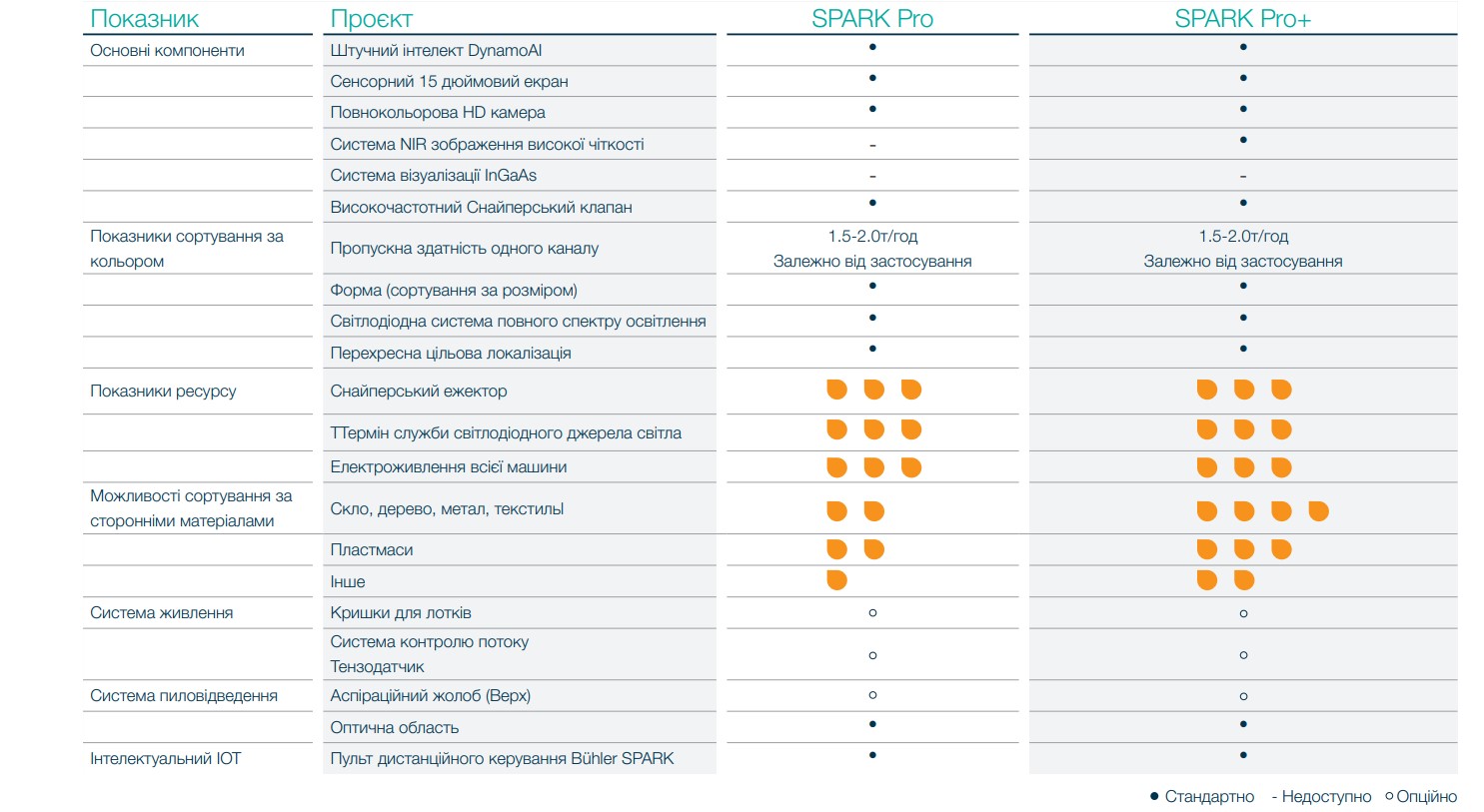

Technical Specifications

Bühler SPARK Pro and SPARK Pro+

Main Specifications Overview