- Bühler Advantages

- Various types of fruit and vegetable products

- Processing process

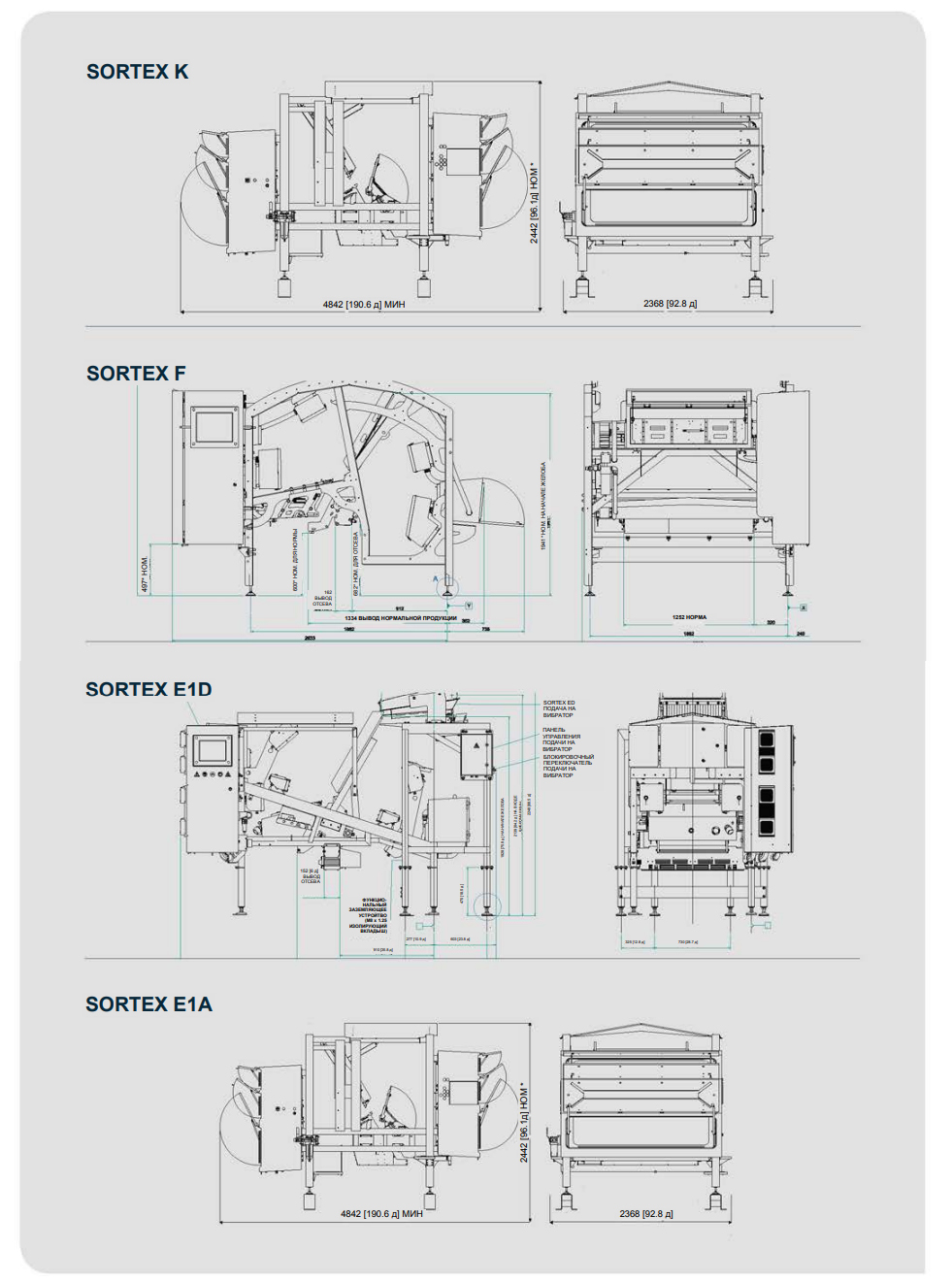

- SORTEX K

- SORTEX F

- SORTEX E1D

- Technologies

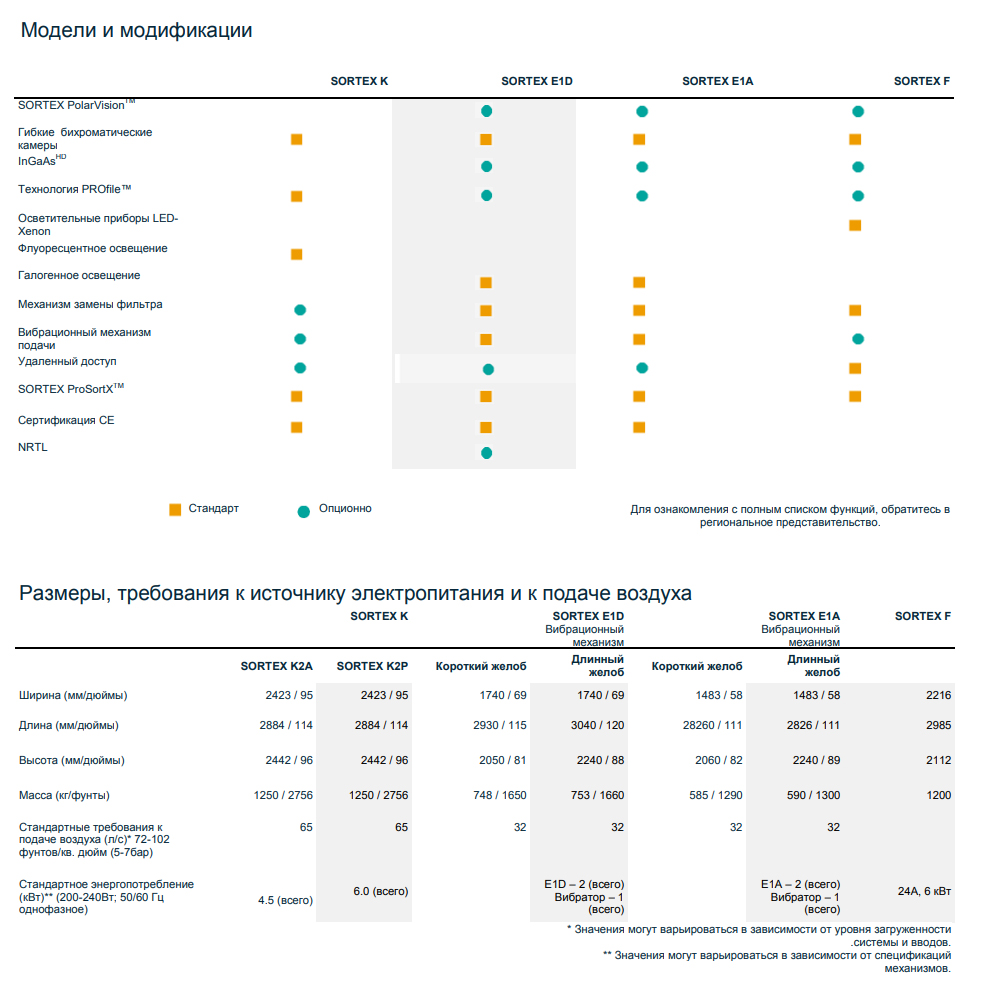

- Model options and specifications

- Customer service

Fruit and vegetable sorting machines of any complexity

1. Bühler is a partnership with processing companies. An integral part of the fruit and vegetable processing industry.

Bühler is a leading supplier of optical sorting equipment for use in food and non-food processing companies and has been at the forefront of optical sorting technology since 1947.

Bühler’s extensive investment in research, development and patented technologies ensures outstanding results in eliminating the most difficult defects and foreign materials in a wide range of fruit and vegetable products.

Fresh and frozen fruit and vegetable processors can be confident in world-class performance when using Bühler optical sorters in their pre-blanching and pre-blanking processing lines.

Key benefits

- Hygienic optical sorters with the lowest risk of contamination.

- Unparalleled defect and foreign material detection.

- Offering advanced optical sorting technologies.

2. Responsible approach to product safety

Simplifying the most challenging sorting conditions

3. Flexible optical sorting systems

At all stages of product processing

- Before blanching

SORTEX® sorters are used before blanching to remove color defects, foreign plant matter (FPM) and field foreign materials, in order to save resources during further processing, which allows for higher production results. - After blanching

Color defects can often be exacerbated during the blanching stage. The use of SORTEX® sorters guarantees the removal of any remaining defects to achieve product uniformity. A reliable method of sorting products prior to freezing, particularly during processing, both before and after blanching, is essential to reduce the risk of microbiological contamination. - After IBF (Individual Quick Freezing)

SORTEX® sorters are equipped with technologies that allow the removal of smaller color defects as well as any deviations from the normal shape of the frozen product remaining. They are also ideal for cleaning processes of large volumes of bulk products, to remove missed PVRP, field foreign matter (FFM) and packaging PM. - On the packaging line

During the final stage of the processing process, there is a risk of packaging PM such as light wood, plastic and cardboard entering the product stream. SORTEX® sorters in the packaging line are optimized to detect a wide range of foreign materials in a simple process operation to ensure high quality, food-safe products.

4. Main processing stage

Processing before and after blanching

SORTEX® K.

The SORTEX® K range of sorters uses an advanced dual-sided detection system to remove the most difficult defects in canned or fresh produce. The high-performance sorter has the ability to inspect blanched or unblanched produce and can be equipped with PROfile™ (Profile Identification by Shape) technology, which provides highly effective detection of PVRP and removal of harmful foreign materials. The SORTEX® K sorter is constructed from hygienic stainless steel with IP56 protection technology.

- 12.1-inch user-friendly touch screen

- Specially designed bichromatic cameras

- 1200 mm optical zone width

- PROfile™ technology

- 256 high-speed and high-performance ejectors

- PowerslideTM conveyor

- Programmable sorting modes

- External USB port for data extraction

- ProSortXTM operating software

5. Main processing stage

After the IBZ and on the packaging line

SORTEX® F.

The new SORTEX® F optical sorter for frozen fruit and vegetable processing plants takes hygienic design to a new level with its open design for best accessibility and a design that is unmatched on the market. This is complemented by revolutionary sorting technologies such as the SORTEX® PolarVision™ detection system with LED-Xenon illumination for highly effective detection of defects and foreign materials.

The SORTEX® F is specifically designed for placement after the IBD or on the packaging line, to remove gross as well as minor color defects, foreign vegetable matter and hazardous foreign materials with the best results on the market.

- Open frame with high-quality hygienic fasteners

- Adjustable trough made of UHMW-PE (ultra-high molecular weight high density polyethylene)

- Open container

- Specially designed bichromatic cameras

- SORTEX® PolarVisionTM detection system

- PROfileTM technology (shape recognition)

- LED-Xenon lighting

- 17-inch touch screen user interface

- ProSortXTM operating software

6. Main processing stage

After the IBS and on the packaging line

SORTEX® E1D.

The SORTEX® E1D sorter offers the consumer all the benefits of high-performance sorting technology in a compact form. Designed to retain the advantages of large sorters for small processing companies, ensuring high quality sorting during the freezing process.

The SORTEX® E1D can be used as a multi-function sorter designed to detect shape and color defects directly after the product passes through the freezer tunnel or at the end of the processing line, using advanced video technology.

The sorter is able to simultaneously remove products with differences in color or shape, minor stains, as well as foreign material and foreign impurities of plant origin with a high degree of accuracy.

- Stainless steel frame for easy cleaning

- UHMW-PE chute

- Double-sided detection system

- Specially designed bichromatic cameras

- InGaAsHD high-resolution technology

- SORTEX PolarVisionTM detection system

- PROfileTM (shape recognition) technology

- 12.1-inch touchscreen user interface

- ProSortXTM operating software

7. Innovative technologies

Simplifying the most complex sorting conditions

8. Model variants

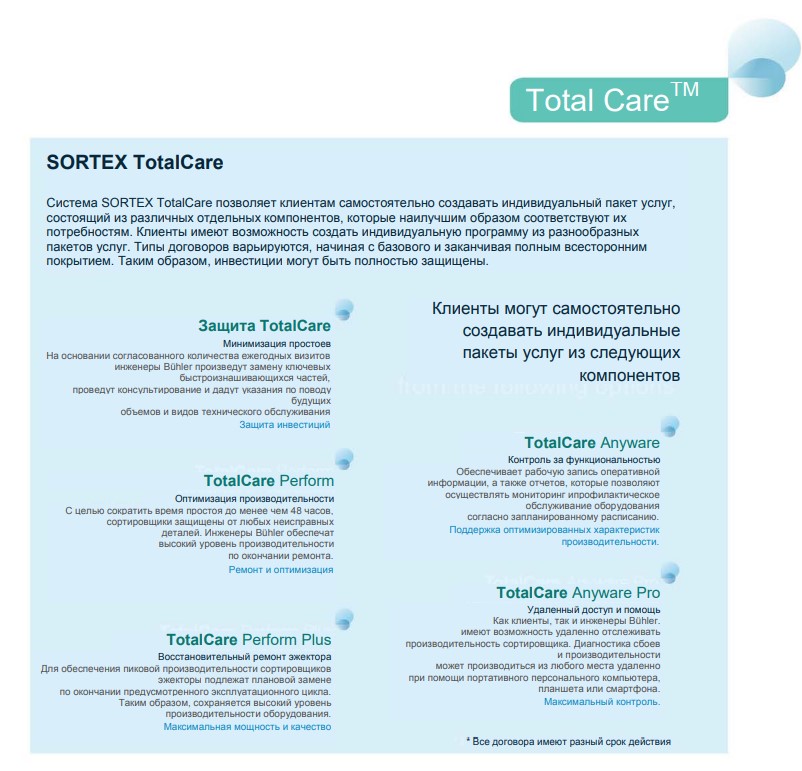

9. SORTEX Customer Service.

Take care of tomorrow’s profits today

The Bühler Customer Service operates worldwide and offers the highest quality local technical support, enabling you to achieve high performance optical sorters, ensuring optimal production efficiency and a high return on investment.

SORTEX® Spare Parts Commitment

Our top priority is high quality customer service. That is why we strive to deliver spare and wear parts within 48 hours, doing everything possible to limit downtime and maximize profitability. For customers who need spare parts, which are available on site, Bühler engineers have created appropriate spare parts kits for different types of existing machines.

SORTEX® Upgrade Kits

Designed for customers who want to upgrade their sorting equipment with an additional module, adding new functions or updating the software. New technologies and innovations are constantly being developed. Equipment upgrade kits allow customers who own our equipment to improve their production performance with the most advanced optical sorting technologies.