SORTEX® F Optical Sorter.

For safe and clean sorting of nuts and dried fruits.

The most hygienic optical sorter in the industry, perfected for nut and dried fruit processors, is now available with

the technology that changed the snack industry – SORTEX BioVisionTM.

SORTEX F combined with SORTEX BioVisionTM technology offers processing equipment nuts and dried fruits 4-in-1 detection of color defects, shells and foreign materials on just one optical sorting platform. The unique open frame design also reduces the risk of bacterial contamination with easy cleaning access, hygienic mounting and inclined surfaces.

The pioneering sorter can be configured for all nut and dried fruit processing industries, from and dried fruit, from primary to secondary processing, including processors, including snack nut manufacturers, nut spreads and nut milks for a versatile solution that focuses on hygienic and efficient sorting at all stages of the processing line. line.

- Hygienic open design with zero tolerance for contamination.

- Available with SORTEX BioVisionTM technology for 4-in-1 color, shell and foreign material detection.

- Detects hazardous materials up to 50% smaller than the current market standard.

SORTEX BioVisionTM

Special technology for detecting nuts.

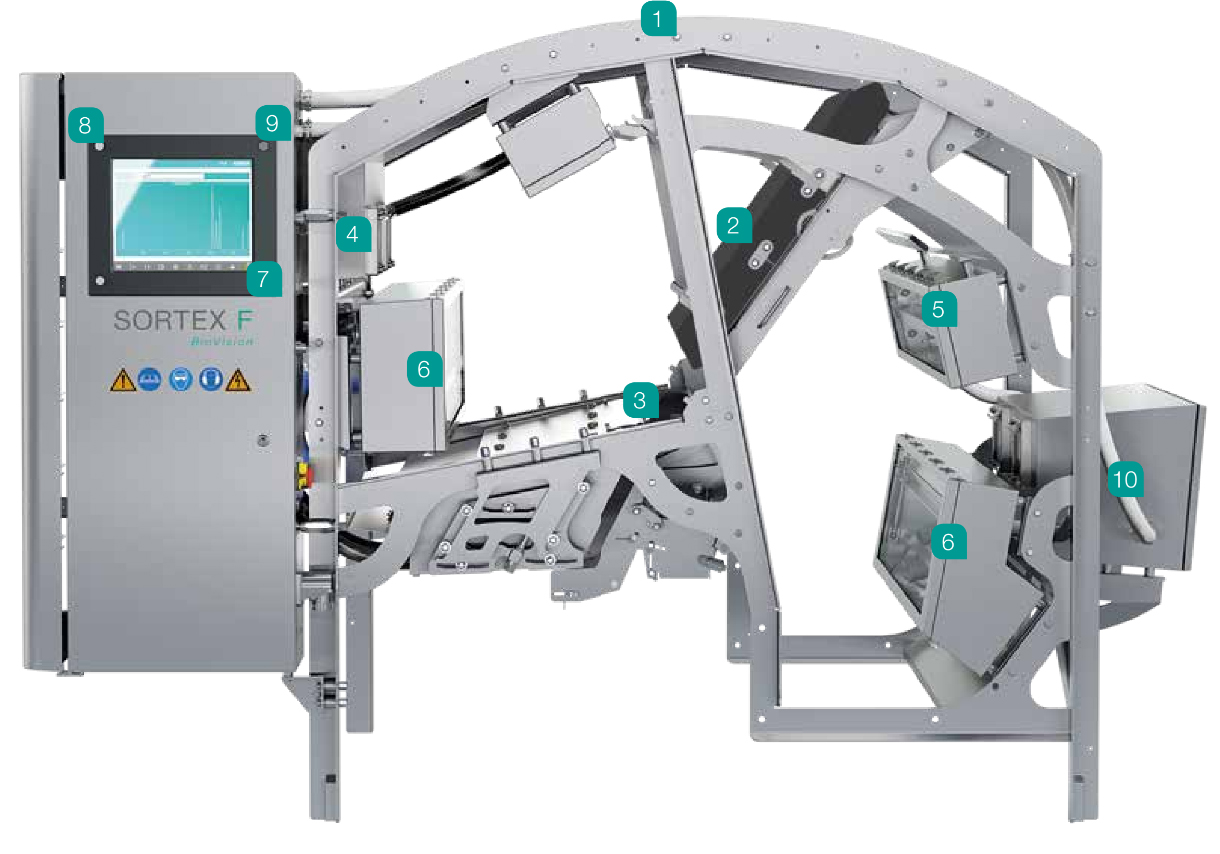

SORTEX® F Optical Sorter. At first glance.

- Available stainless steel frame

Every element from the stainless steel frame, inclined surfaces to the hygienic screws has been carefully selected with food safety in mind – leaving no detail untouched. - Anodized, adjustable chute

The anodized chute, available in 600 mm and 1200 mm sizes, provides an easy-to-clean surface for processing nuts. Increased productivity with resort recycling capability, chutes are easily adjustable, giving operators greater access to the inside of the machine. - Unique open vessel

The unique to Bühler vessel is easy to open and close and close to provide access for cleaning, reducing the risk of contamination. This bin is combined with a state-of-the-art dust extraction system, creating an optimal working environment. - State-of-the-art detection system

Available with innovative SORTEX BioVisionTM technology – a unique configuration of detection technologies including BioCamTM combined with InGaAsHD clarity or color cameras, or both – to simultaneously detect color, shell and foreign material defects. - LED XENON foreground illumination

Provides uniform, broad spectrum illumination across the entire field of view for greater uniformity with less shadowing. - LED background

With red, green and blue backgrounds, processors can determine the optimal sorting mode regardless of the product being sorted. - Larger, 17-inch user-friendly interface

The improved user interface features a larger screen and controls, simplifying operator usability. - SORTEX ProSortXTM Operating Software

The new SORTEX ProSortXTM software comes standard. It features a fresh new interface that is modern, clean and intuitive to use. - Intelligent Sorting Capabilities

With self-learning capabilities with pre-set and user-defined sorting modes, “push and forget” sorting minimizes operator intervention. - Ultra-modern cooling system

By maintaining a constant temperature throughout the sorting function, this integrated system ensures consistent component performance and product quality.

SORTEX® F Optical Sorter Technologies. Innovation and Leadership.

From competence centers around the world and our Optical Sorting headquarters in London, our researchers, engineers and product developers work in partnership with our customers to develop proprietary technologies that are at the forefront of optical sorting – since 1947.

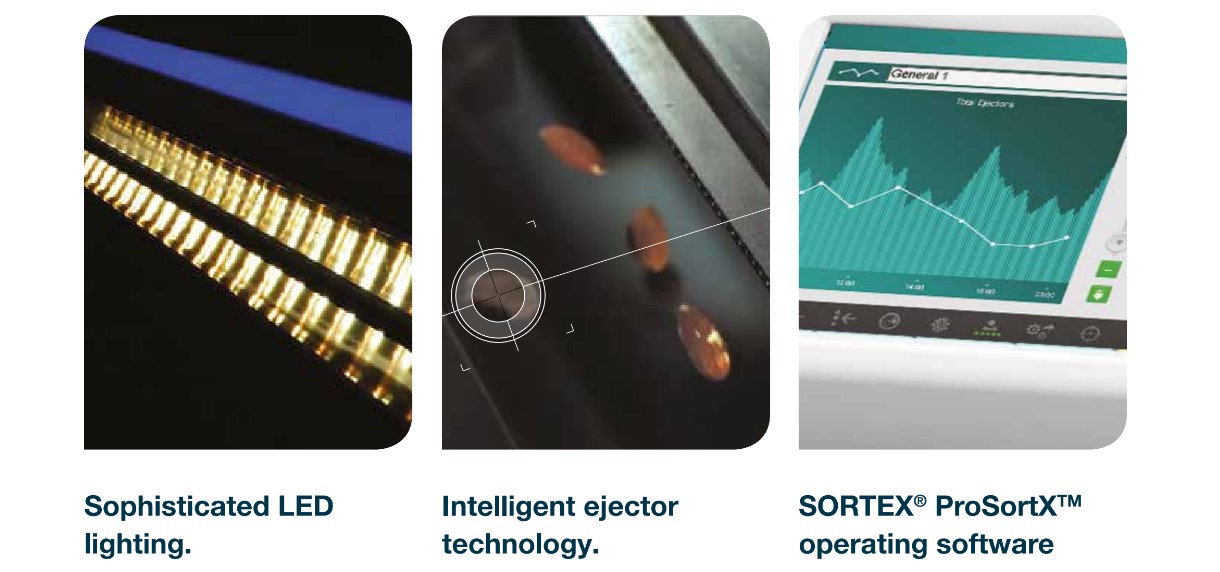

Sophisticated LED lighting

The sophisticated LED-xenon foreground illumination provides maximum illumination with a wide spectrum for greater uniformity with less shadowing, while the new LED background illumination is available in red, red, green or blue to ensure optimal sorting performance, regardless of the application being sorted.

Intelligent ejector technology

SmartEjectTM – high speed, high flow ejectors efficiently remove defects with high precision and accuracy. Ejector+ technology, Bühler’s most powerful ejectors, is available as an option for the SORTEX F optical sorters for the removal of heavy objects such as stones and glass.

SORTEX® ProSortXTM operating software

The latest update to Bühler’s proprietary software, the Bühler operating software, comes with a fresh new interface that is modern, clean and intuitive to use. Featuring the innovative FingerTipControlTM and the brand new Bühler ATOMTM board for faster processing and navigation between screens.

SORTEX® F Optical Sorter. Safety, Hygiene, Design and Productivity.

Designed with food hygiene and safety in mind.

SORTEX BioVisionTM Technology Feature

BioVisionTM is a set of technologies available only on Buhler SORTEX optical sorters. A combination of high-definition infrared radiation, shape recognition technology and biochromatic color recognition. In conditions of increased requirements for food safety and hygiene, in order to meet customer expectations, BioVisionTM technology is a unique tool for ensuring the highest quality nuts, allowing you to get the cleanest and safest product.

SORTEX® BioCamTM

The advanced SORTEX BioVisionTM detection system is a unique configuration of detection technologies that includes BioCamTM combined with InGaAsHD, color cameras and PROfileTM technology. Innovative BioCamTM technology aims to detect spectral and spatial differences between quality product and casing, new high-resolution InGaAsHD cameras detect foreign materials in the near-invisible infrared spectrum and custom-made visible range eliminate color defects, including dark, rotten, yellow and spotted defects.

High definition InGaAsHD technology

Bühler’s next-generation infrared detection is now available in high definition with double the resolution for detecting foreign objects up to half the size. With twice the number of pixels, InGaAsHD detects the smallest particles of hazardous materials that cannot be seen in the visible spectrum, providing an additional level of safety.

Color, shell and foreign object detection – all in one.

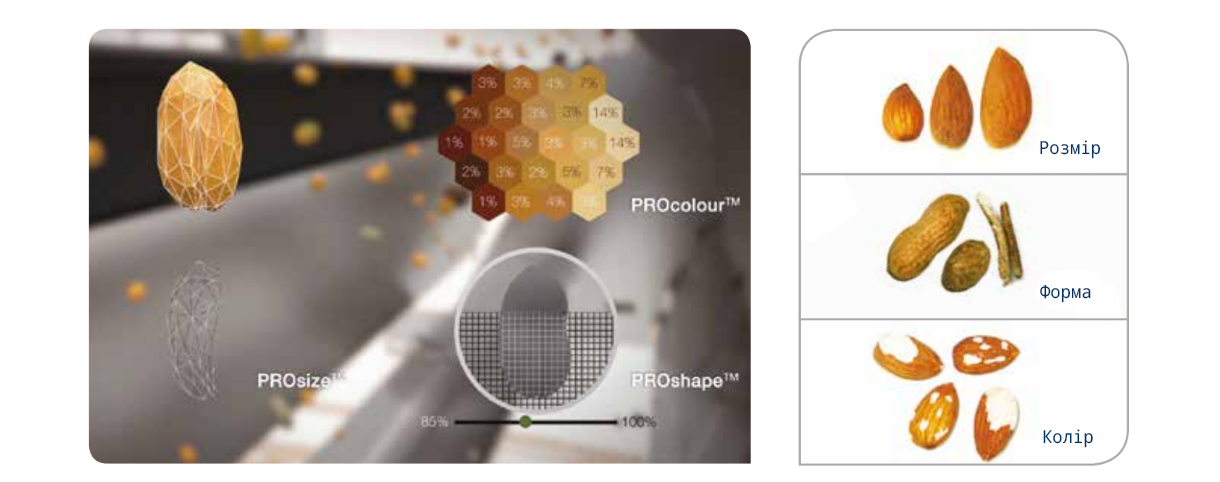

SORTEX® Technology PROfileTM

A combination of three dynamic technologies that enable Bühler optical sorters to handle even the most challenging sorting tasks. Designed with multiple levels of shape, size and color recognition to ensure consistent, uniform product quality at the highest possible productivity. product quality at the highest possible productivity. This unique dual detection system analyzes the product from both sides to offer processors a complete quality guarantee.

PROsizeTM

A significant departure from traditional sorting solutions, PROsizeTM can be used in situations where the product is too delicate or difficult to sort with conventional mechanical sorters, maximizing profitability by separating premium products.

PROcolourTM

Processors can determine the maximum percentage of surface defects based on retail or customer specifications, allowing them to classify products by appearance and maximize market value by identifying multiple grades of quality product.

PROshapeTM

PROshapeTM is an intelligent detection technology that checks a product based on shape criteria when a defective product has the same color as a good product.

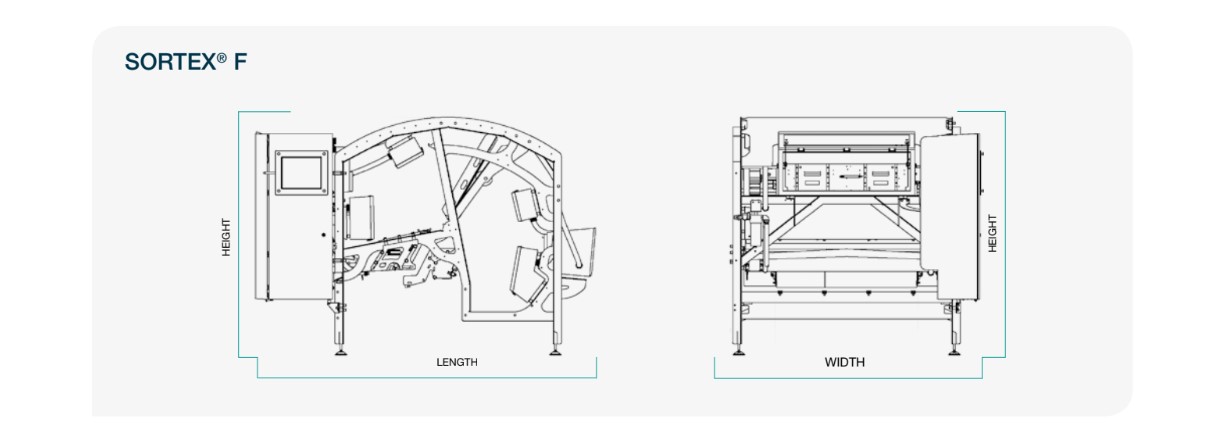

Model variants and technical specifications.

Product variants

Caring for SORTEX® customers. Ensure tomorrow’s profits today.

Bühler customers have access to a network of more than 140 sales and service offices worldwide, offering customized service packages, spare parts inventory and upgrade kits to keep your optical sorters running at peak efficiency. Training courses and competence centers offering product and program testing are also available at regional offices and local offices worldwide.

TotalCareTM

Create a customized service package consisting of individual service functions from the list below. From maintenance visits, downtime coverage to rebuilds and preventive maintenance – from basic to fully comprehensive. Designed to ensure maximum performance from your optical sorters.

TotalCare protects

Minimize downtime

Based on an agreed number of annual visits, Bühler engineers will replace key wear parts and provide advice and guidance on further maintenance.

TotalCare Perform

Optimize performance

With the aim of reducing downtime to 24 hours, the sorters are protected from any component failure. Bühler engineers will ensure top-notch performance after the repair.

TotalCare PerformPLUS

Ejector renewal

To ensure that the sorters operate at peak performance, the ejectors are replaced when the expected life cycle is reached. Performance is maintained well into the future.

TotalCare Anyware Software

Controlled functionality

Provides a working record of operational information as well as reports that allow you to monitor the machine’s condition and plan preventive maintenance.

TotalCare AnywarePRO

Remote access and assistance

The sorter’s performance can be viewed remotely by customers and Bühler engineers. Faults can be diagnosed and performance optimized from anywhere using a laptop, tablet or smartphone.

All contract options are available for different durations.

SORTEX® Spare Parts Promise

Satisfying your customers’ needs is our priority. That’s why we strive to deliver both spare and wear parts within 48 hours, maximizing your profitability.

SORTEX Spare Parts

For customers who want to have spare parts on site, different kits are available for different optical sorters. customers who want to have spare parts on site.

SORTEX® Retrofit Kits

Bühler has developed different retrofit kits for existing customers who want to upgrade their sorters with add-on modules, new process functions or software.

Optical Sorting Training Courses

Available at various Bühler regional offices. From operator to supervisor, basic to advanced, contact your local representative for course selection and availability.